Introduction to Okamoto Igm15nc Toy Shaft

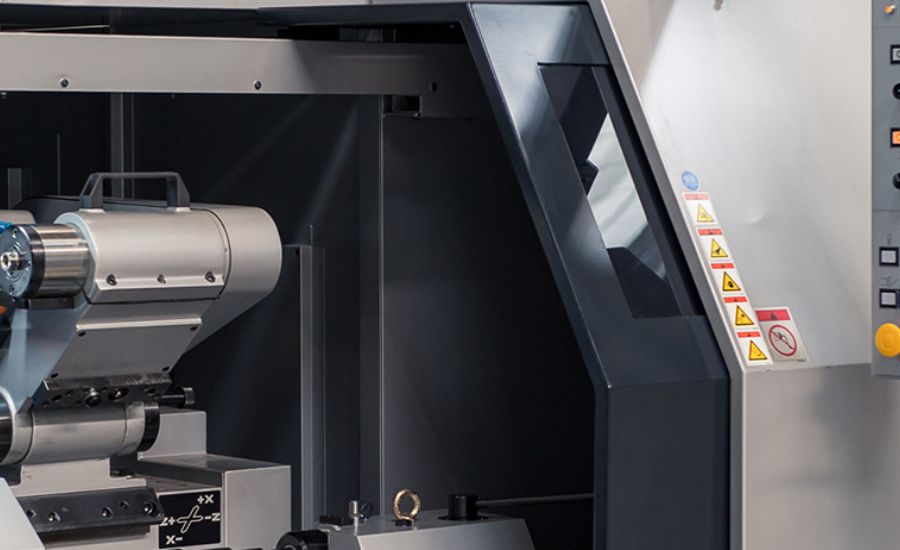

The speed at which technology is developing in the field of precision grinding is extremely rapid. One innovation that is attracting attention is the Okamoto IGM15NC Toy Shaft. This state-of-the-art device is revolutionizing the way industries approach accuracy and efficiency by establishing new benchmarks for high-precision machining and production.

Consider a tool that is not only intended to boost output but also continuously produces work of the highest caliber in each and every action. Having dependable and effective equipment is more important than ever because of the increasing need for precision components across a range of sectors. These requirements are satisfied by the Okamoto IGM15NC Toy Shaft, which provides unparalleled accuracy and dependability.

We will examine the Okamoto IGM15NC Toy Shaft’s amazing capabilities and how it is revolutionizing precision grinding in several industries in this blog post. This is the ideal location to learn about the future of effective, high-quality production, regardless of your level of experience in the field or your general curiosity about the newest advancements in manufacturing technology.

What is the Okamoto IGM15NC Toy Shaft?

High-end, highly precise, and designed for complex equipment applications is the Okamoto IGM15NC Toy Shaft. The IGM15NC Toy Shaft, manufactured by Okamoto, a well-known leader in machine tool manufacturing, is designed to provide outstanding performance, long-lasting durability, and great efficiency.

This shaft performs exceptionally well in settings where accuracy and wear resistance are crucial due to its creative design and painstaking manufacturing procedures. The IGM15NC Toy Shaft is more than just a simple part; it is essential to improving the entire operation of the machine and guaranteeing optimal performance at all times.

Key Features of the Okamoto IGM15NC Toy Shaft

One of the best examples of precise engineering in toy manufacture is the Okamoto IGM15NC Toy Shaft. This shaft is a popular option for toy manufacturers because of its distinctive features.

Precision lies at the core of the Okamoto IGM15NC. It constantly produces excellent results with tight tolerances, guaranteeing consistency in every product. Every unit operates to the highest standards thanks to the shaft’s proportions, which adhere to strict industry norms.

The shaft is made of premium steel and has a long lifespan and resilience to wear. Surface treatments further reinforce it. Because of this, it can withstand a lot of stress without losing its form or functionality.

The Okamoto IGM15NC has flawless geometry and smooth surfaces thanks to sophisticated production processes that include precise grinding. To satisfy stringent engineering requirements, every shaft is subjected to rigorous quality control.

This shaft’s efficient design minimizes material consumption and friction, guaranteeing dependable, high-quality performance in a variety of toy-making applications. The Okamoto IGM15NC is a reliable component for a wide range of production demands since toy producers can count on it to deliver consistent results.

The Technology Behind Precision Grinding

One significant development in contemporary manufacturing is precision grinding technology. Fundamentally, it uses advanced equipment to produce immaculate surface finishes and extremely tight tolerances.

CNC (Computer Numerical Control) technology are used in the Okamoto IGM15NC Toy Shaft to automate the grinding operation. Operators can effortlessly design complex geometries thanks to this automation, which ensures that every cut is accurate, repeatable, and extremely efficient.

High-performance grinding wheels, which are made to maximize material removal while guaranteeing superior quality, are also used by the machine. These wheels offer great versatility for a variety of applications and can be customized for certain jobs.

The system is equipped with vibration-dampening characteristics to enhance performance even more. These reduce operational disruptions, improving precision and prolonging the life of the tool and workpiece.

Operators can continuously observe the grinding process thanks to real-time feedback devices. These kinds of innovations have transformed conventional processes into sophisticated ones, empowering producers to confidently and effectively satisfy the demanding expectations of modern industries.

Applications of the Okamoto IGM15NC Toy Shaft

1. Automotive Manufacturing

The Okamoto IGM15NC Toy Shaft is essential to maintaining the highest standards of quality in a variety of industries where accuracy is critical.

Automobile Sector

Precision is essential in the production of automotive components such as bearings, camshafts, and crankshafts. Strict standards are met by the Okamoto IGM15NC Toy Shaft, guaranteeing that these parts enhance the longevity, dependability, and performance of automobiles.

Components of Aerospace

For safety and functionality, aerospace parts require the greatest standards of accuracy. In order to fulfill the exacting standards needed in this industry, the Okamoto IGM15NC Toy Shaft is crucial for grinding crucial inside surfaces of turbine components, actuators, and other aerospace parts.

Production of Heavy Machinery

For heavy machinery to operate smoothly, its parts need to be precise and robust. By enhancing these components’ performance and durability, the Okamoto IGM15NC Toy Shaft reduces maintenance requirements and increases the machinery’s lifespan.

Medical Devices and Equipment

The Okamoto IGM15NC Toy Shaft contributes to the production of surgical tools, diagnostic equipment, and other medical devices with perfect finishes, satisfying the exacting requirements necessary for these life-critical applications in the medical sector, where accuracy has a direct impact on patient safety.

Shaping the Future of High-Performance Grinding

An insight into the future of industrial grinding can be gained by observing the Okamoto IGM15NC Toy Shaft in action. It is a leader in contemporary production equipment because of its remarkable adaptability and state-of-the-art characteristics.

The IGM15NC Toy Shaft raises the bar for accuracy whether it is used to improve safety in aircraft or to produce high-performance parts for the automotive sector. Every cut and grind demonstrates how the technology can push limits and influence how manufacturing is done globally in the future.

Elevate Your Machinery’s Performance with Okamoto

A true example of engineering excellence, the Okamoto IGM15NC Toy Shaft is more than just a mechanical component. It embodies the essential qualities that industries require to stay competitive with its remarkable accuracy and robust design.

The Toy Shaft offers exceptional dependability and performance whether you are working on advanced robots or complex aeronautical systems.

Do you want to see the difference for yourself? See how the Okamoto IGM15NC Toy Shaft’s long-lasting sturdiness and precise engineering can improve the capabilities of your machines by integrating it into your operations.

The Okamoto IGM15NC Toy Shaft and Industry 4.0

With devices like the Okamoto IGM15NC Toy Shaft at the forefront, the transition to Industry 4.0 is revolutionizing the manufacturing sector. Peak performance is ensured by its CNC features, which allow for real-time monitoring and modifications. Furthermore, operations are optimized, downtime is reduced, and overall efficiency is increased by its smooth connection with digital systems.

Manufacturers may maintain their lead in a constantly changing business by utilizing cutting-edge technology to continuously provide excellent outcomes by implementing the Okamoto IGM15NC Toy Shaft.

Tips fczor Maintaining the Okamoto IGM15NC Toy Shaft

Maintaining a good maintenance schedule is essential to ensuring the Okamoto IGM15NC Toy Shaft continues to operate at its best over time. Here are some important pointers:

Regular Cleaning: Thoroughly clean the shaft after every usage to get rid of any residue or debris that can impair its functionality and harm internal parts.

Regular Inspections: Arrange for routine examinations to identify possible problems early and avoid any significant malfunctions.

Sufficient Lubrication: To maintain seamless operations and prevent excessive wear, make sure all moving parts are adequately lubricated.

Operator Training: Give your personnel the instruction they need to operate the equipment efficiently and with the fewest possible dangers.

The Okamoto IGM15NC Toy Shaft will continue to operate at its peak for many years to come if these easy yet crucial actions are taken.

Features and Benefits of the Okamoto IGM15NC Toy Shaft

The advanced CNC grinding technology of the Okamoto IGM15NC Toy Shaft makes it stand out. This machine was designed with precision in mind, making sure every part satisfies exacting requirements and providing unparalleled accuracy.

Because of its intuitive interface, even novices and seasoned professionals may operate it with ease. Real-time data monitoring is provided by the touchscreen controls, increasing total productivity.

High-quality materials are used in the shaft’s construction to provide long-lasting performance and resistance to rigorous use.

Another noteworthy aspect is automation, which increases productivity and lowers the possibility of human error. Even throughout lengthy manufacturing runs, this guarantees reliable, superior outcomes.

The Okamoto IGM15NC Toy Shaft is also energy-efficient, consuming less power while still providing excellent performance. Because of these characteristics, it is an invaluable tool for any industrial process aiming for superior machining.

Comparison with Traditional Grinding Methods

The Okamoto IGM15NC Toy Shaft’s variations from conventional grinding techniques are readily noticeable. Longer production times and greater operating expenses result from traditional systems’ frequent reliance on antiquated, sometimes slower, and less effective methods.

In contrast, the Okamoto IGM15NC has automation that significantly lowers the possibility of human error. As a result, operators can devote more time to other crucial duties and less time to maintaining the machine.

The decrease in waste is still another significant benefit. The Okamoto IGM15NC’s precision guarantees little waste, making it a more environmentally responsible option for producers than traditional grinding methods, which frequently result in higher scrap rates.

Speed is also important. The Okamoto IGM15NC produces results in a fraction of the time without compromising quality, whereas older methods can take a lot longer to do a project.

In addition to increasing efficiency, these technical developments create new growth opportunities across a range of businesses.

Facts:

- Manufactured by Okamoto: A leading name in machine tool manufacturing.

- Precision CNC Grinding: Uses automated systems for accurate, repeatable cuts with tight tolerances.

- Durable Construction: Made from high-grade steel with surface treatments for wear resistance.

- Applications: Automotive, aerospace, heavy machinery, and medical device production.

- Efficiency: Reduces scrap, waste, and downtime while enhancing performance and longevity.

- Advanced Features: Includes vibration-dampening technology and real-time feedback monitoring.

- Energy-Efficiency: Consumes less power without compromising performance.

- Maintenance: Requires regular cleaning, inspection, lubrication, and operator training to ensure longevity.

Summary:

The Okamoto IGM15NC Toy Shaft is a cutting-edge piece of machinery designed for precision grinding, revolutionizing manufacturing across industries. This high-performance shaft delivers exceptional accuracy, durability, and efficiency, making it an invaluable tool for producing components that meet tight tolerances and high industry standards. By utilizing advanced CNC technology, real-time feedback systems, and vibration-dampening features, the IGM15NC ensures consistency, reduces waste, and enhances productivity. Its versatile design is suitable for applications in automotive, aerospace, heavy machinery, and medical sectors, making it an essential asset for modern manufacturing setups aiming for excellence.

FAQs:

- What makes the Okamoto IGM15NC Toy Shaft so precise?

- The IGM15NC uses advanced CNC technology, which ensures automated, highly accurate cuts with minimal variation. Its precise manufacturing processes, including high-performance grinding wheels and vibration-dampening systems, further enhance its accuracy.

- What industries benefit from using the Okamoto IGM15NC Toy Shaft?

- The IGM15NC is suitable for industries that require precise components, including automotive, aerospace, heavy machinery, and medical devices.

- How does the IGM15NC reduce waste compared to traditional grinding methods?

- The precision of the IGM15NC significantly reduces scrap rates, unlike traditional grinding methods, which often produce higher amounts of waste material due to less accurate cuts.

- What are the maintenance requirements for the Okamoto IGM15NC Toy Shaft?

- Regular maintenance includes cleaning the shaft after use, scheduling periodic inspections, ensuring proper lubrication of moving parts, and providing thorough operator training.

- Is the Okamoto IGM15NC Toy Shaft energy-efficient?

- Yes, the IGM15NC is designed to consume less energy while maintaining high performance, contributing to more sustainable production practices.

- How does the IGM15NC enhance productivity?

- Its automated systems reduce human error and operational downtime, while its advanced features (like real-time monitoring and automated adjustments) streamline workflows, ensuring consistent, high-quality results with minimal manual intervention.

Read more Information about Technology at Visit SearchKnowledge.org

Leave a Reply