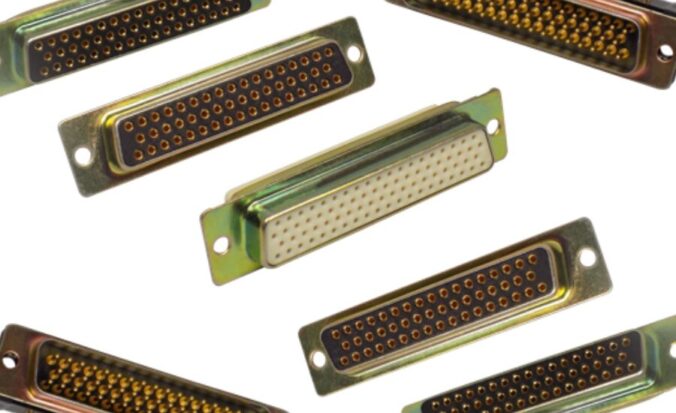

Introduction To Connector dpxbmas21000-2286 per mil-c-81659

When it comes to military-grade equipment, reliability isn’t optional—it’s essential. Among the many critical components ensuring seamless operation in defense systems, the DPXBMA 21000-2286 connector, designed to meet Mil-C-81659 standards, stands out. This high-performance connector is vital for secure communication and power transfer in some of the most demanding environments.

But what makes this connector so crucial for military applications? How has its design evolved over time to meet the growing demands of modern defense technology? In this blog, we’ll explore its history, technical specifications, and the future of military-grade connectivity.

The Importance of Connector DPXBMA 21000-2286 in Military Technology

Built to strict military standards, the DPXBMA 21000-2286 connector ensures seamless functionality even in the harshest environments. For those interested in defense technology, knowing its role highlights the precision and innovation behind military-grade equipment. Military operations require equipment that can withstand extreme conditions—from freezing cold to intense heat—while maintaining peak performance.

The Role of MIL-C-81659 in Connector Standards

A crucial industry standard, MIL-C-81659, establishes stringent performance and dependability specifications for connectors such as the DPXBMA 21000-2286. According to this military specification, connectors can withstand severe circumstances including shock, vibration, and abrupt temperature changes without losing their ability to function. Following MIL-C-81659 improves these parts’ robustness and dependability, giving mission-critical military systems the dependability they need.

History and Evolution of Connector DPXBMA 21000-2286

The MIL-C-81659 standard, a strict set of rules created to guarantee uniformity, dependability, and excellent performance in military-grade connections, serves as the basis for the DPXBMA 21000-2286 connector. With time, improvements in design, manufacturing techniques, and materials have made this connector a cutting-edge option for contemporary defense applications.

Early military connectors were made for primitive communication systems and were rather basic. However, the demand for stronger and more effective connectors increased as military technology developed. In response to these growing needs, the DPXBMA 21000-2286 was developed with higher conductivity, increased durability, and sophisticated sealing mechanisms to endure even the harshest circumstances.

The Versatility of DPXBMA 21000-2286: Where It Shines

Sector-Specific Applications: Aerospace, Defense, and Beyond

Aerospace Integration: The DPXBMA 21000-2286 connector is crucial to the aerospace sector’s ability to sustain dependable system operations under the harsh circumstances of high altitudes and space settings.

Defense Dependability: This connector guarantees secure, continuous connectivity for defense applications, which is essential for mission and operation success.

Industrial Reliability: The DPXBMA 21000-2286 offers the dependability required in industrial settings to maintain equipment and procedures operating efficiently, even under the most trying circumstances.

Installation and Operational Guidance for DPXBMA 21000-2286

Best Practices for Installation:

Installation Advice: This section provides comprehensive instructions on how to install the DPXBMA 21000-2286 connector correctly, guaranteeing optimal performance and long-term dependability. Maintenance Advice: In this section, we go over crucial maintenance procedures that support the connector’s integrity and functionality, guaranteeing its continuous dependability over time.

Technical Breakdown of Connector DPXBMA 21000-2286

In military applications, why is the DPXBMA 21000-2286 connector unique? The following technical details demonstrate why it is a preferred part of defense systems:

Materials: This connector is made of high-quality alloys and composite materials that are resistant to wear and corrosion, guaranteeing enduring performance even under challenging conditions. In order to retain optimal operation, the insulating materials are precisely selected based on their capacity to withstand high temperatures and block electrical interference.

Durability: This connector is made to withstand impact, stress, and vibration and keeps its connection intact in harsh circumstances. It is appropriate for use on land, at sea, and in the air because it is sealed to keep out environmental factors including dust, water, and moisture.

Electrical Performance: The DPXBMA 21000-2286 can handle high power loads without running the risk of overheating thanks to its strong conductivity. Reliable communication is ensured by its exceptional signal integrity, which is essential for military operations when communication dependability can make the difference between success and failure.

These design elements demonstrate the sophisticated engineering that went into this connector, which makes it a reliable option for military applications that are crucial to the mission.

How the Connector Meets Mil-C-81659 Standards

One of the strictest requirements for military connectors is the Mil-C-81659 standard, which guarantees dependable operation even in the most hostile conditions. These exacting requirements are not only met, but frequently exceeded, by the DPXBMA 21000-2286 connector. The following are the main characteristics that meet Mil-C-81659 requirements:

Temperature Tolerance: This connector is made to withstand extreme temperatures, ranging from -55°C to +125°C, guaranteeing dependability in both extremely hot and extremely cold conditions.

Environmental Sealing: The connector’s high level of ingress protection (IP) prevents water and dust penetration, making it perfect for usage in a variety of demanding outdoor environments.

Resistance to Mechanical Stress: The connector is designed to endure severe impacts, shocks, and vibrations while still being connected even in the face of severe physical strain.

Corrosion Resistance: Even in humid or salty conditions, the connector is shielded from rust and other types of corrosion by special coatings and materials that have been carefully chosen.

The DPXBMA 21000-2286 is an essential component of defense technology since it complies with the Mil-C-81659 standard, which guarantees that it can withstand the demanding and uncertain conditions common to military operations.

Future Trends in Military Connector Technology

Connector technology is changing to keep up with the ongoing advancements in military technology. The following are some anticipated advancements in the field:

Miniaturization: Future connectors will be lighter and more compact, which will enable military equipment weigh less overall while still delivering excellent performance.

Improved Data Transfer Capabilities: Connectors will be built to manage greater data transfer rates without compromising dependability in response to the military systems’ increasing need for more bandwidth.

Connectors with sensors and intelligence systems that can track their own performance are known as “smart connectors.” This enables them to identify possible problems and anticipate breakdowns before they occur.

Advanced Materials: As materials science advances, connectors will become even more robust and long-lasting, able to tolerate more extreme environmental conditions.

With its ability to adapt to these developments, the DPXBMA 21000-2286 connector will continue to be essential to the advancement of military technology.

The Lifeline of Military Systems

Built to Mil-C-81659 requirements, the DPXBMA 21000-2286 connector is much more than just a component; it is an essential lifeline for military systems, guaranteeing reliable power transfer and communication even under the most hostile conditions. Precision engineering is crucial for defense applications, as evidenced by its rigorous adherence to military criteria and continuous design and technological developments.

Understanding parts like the DPXBMA 21000-2286 demonstrates the intricacy and accuracy needed in contemporary military systems to those who are enthusiastic about military technology. This link is essential to maintaining national security and saving lives, whether it is through improving aircraft systems, assisting with ground operations, or guaranteeing secure communications.

Case Studies Highlighting the Use of Connector DPXBMA 21000-2286

The DPXBMA 21000-2286 connector is essential to many military systems and platforms. Here are a few noteworthy instances that demonstrate its importance:

Defense Communications Systems: It ensures dependable signal transmission for people during field operations and is utilized in tactical radios and encrypted communication devices.

Military Aircraft: Supporting avionics systems, the connector offers reliable and secure power and data connections that are essential for communication and navigation.

Ground Vehicles: It connects crucial parts like targeting systems and sensors to tank and armored vehicle systems, guaranteeing their smooth operation.

Naval Applications: To ensure continuous operation in demanding maritime settings, the connector is crucial for naval vessels’ sonar and radar systems.

These illustrations highlight the adaptability and dependability of the DPXBMA 21000-2286 connector, which makes it essential for use in a variety of military branches.

Facts

- Connector Name: The connector DPXBMA 21000-2286 adheres to the MIL-C-81659 standard.

- Primary Function: It ensures reliable communication and power transfer for military systems in extreme environments.

- Material Composition: The connector is made of high-grade alloys and composite materials, resistant to corrosion and wear, ensuring longevity in demanding conditions.

- Environmental Durability: Designed to withstand shock, vibration, temperature fluctuations, and environmental factors like dust and moisture, making it ideal for military applications on land, sea, and air.

- Temperature Range: It operates in temperatures ranging from -55°C to +125°C.

- Electrical Performance: High conductivity ensures it can handle substantial power loads without overheating, making it crucial for military communication systems.

- Industry Standard Compliance: It meets the stringent MIL-C-81659 standards, ensuring it can function in harsh military environments.

- Versatility: The connector is used across various military applications, including defense communications, aircraft avionics, armored vehicles, and naval systems.

Summary

The DPXBMA 21000-2286 connector, built to MIL-C-81659 standards, is essential for ensuring reliable communication and power transfer in military systems that operate in extreme conditions. Its robust materials, exceptional durability, and electrical performance make it crucial for defense applications in aerospace, ground vehicles, and naval systems. The connector is designed to handle harsh environments, including extreme temperatures, mechanical stress, and environmental factors like moisture and dust. As military technology continues to evolve, the DPXBMA 21000-2286 connector is poised to adapt to future trends such as miniaturization and enhanced data transfer capabilities, ensuring its continued importance in military systems.

FAQs

1. What is the DPXBMA 21000-2286 connector? The DPXBMA 21000-2286 is a military-grade connector built to MIL-C-81659 standards, providing reliable communication and power transfer for military equipment in extreme environments.

2. Why is the DPXBMA 21000-2286 connector important in military applications? This connector ensures seamless performance in harsh conditions, including extreme temperatures, shock, vibration, and environmental exposure, making it crucial for mission-critical military systems.

3. What are the primary features of the DPXBMA 21000-2286? Key features include high durability, resistance to corrosion, superior electrical performance, environmental sealing, and the ability to withstand extreme mechanical stress and temperature fluctuations.

4. What military sectors use the DPXBMA 21000-2286? The connector is used across various sectors, including aerospace, defense communications, ground vehicles, and naval applications, supporting avionics systems, tactical radios, armored vehicles, and sonar/radar systems.

5. How does the DPXBMA 21000-2286 meet MIL-C-81659 standards? The connector meets rigorous requirements for temperature tolerance, environmental sealing, resistance to mechanical stress, and corrosion, ensuring reliable operation in demanding military conditions.

6. What are future trends in connector technology that the DPXBMA 21000-2286 may adapt to? Future trends include miniaturization, enhanced data transfer capabilities, the development of smart connectors, and advancements in materials science, all of which the DPXBMA 21000-2286 is expected to incorporate.

7. How does the DPXBMA 21000-2286 benefit military systems? It ensures reliable and uninterrupted communication, power transfer, and data exchange across military systems, enhancing operational success in the field, whether in air, on land, or at sea.

Read more about Technology at Visit SearchKnowledge

Leave a Reply