Introduction to 1992 Corvette Remover Tail Lighting Fixtures For Led Load Resistor

Upgrading your car’s lighting fixtures machine can carry each greater style and improved visibility. If you’re a proud 1992 Corvette proprietor seeking to transfer to LED tail lighting fixtures, you could come upon a commonplace 1992 corvette remover tail lights for led load resistor undertaking: the need for a load resistor. In this certain guide, we’ll smash down why load resistors are vital while upgrading to LED tail lighting fixtures, a way to well installation them, and the benefits they provide. Additionally, we’ll cover commonplace questions to make sure you’re fully equipped with the information wanted to complete your improve successfully.

Why Upgrade to LED Tail Lights for a 1992 Corvette?

Upgrading to LED tail lighting for your 1992 Corvette can offer quite a number benefits, making it a famous choice among car fanatics. The transition from traditional incandescent bulbs to LEDs now not handiest enhances the look of your car however also improves its ordinary performance. Let’s discover the motives why upgrading to LED tail lighting fixtures may be a outstanding decision to your Corvette.

1. Improved Visibility and Brightness

One of the important thing advantages of switching to LED tail lights is the large growth in brightness. LED lighting emit a much brighter, greater focused light as compared to incandescent bulbs. This development in visibility makes your car more substantial to different drivers, particularly in low-mild situations or at night time. The more suitable brightness can also contribute to better safety by allowing different drivers to spot your automobile quicker.

2. Longer Lifespan

LED lighting are known for his or her durability and long lifespan. Unlike traditional bulbs, which normally burn out after a sure length, LEDs can ultimate a great deal longer, lowering the need for frequent replacements. This longevity interprets into 1992 corvette remover tail lights for led load resistor fewer journeys to the mechanic or vehicle parts shop, ultimately saving you time and cash on maintenance.

3. Energy Efficiency

Another compelling motive to improve to LED tail lights is their electricity efficiency. LEDs devour a long way less energy in comparison to traditional incandescent bulbs, which allows preserve your car’s battery life. This lower energy intake also can alleviate stress in your automobile’s electric machine, ensuring it runs extra successfully.

4. Sleek, Modern Appearance

LED tail lights give your Corvette a swish, modern-day look. The sharp, smooth strains of LED lights add a elegant contact that can raise the general aesthetic of your car. Whether you’re attending car shows or really using round town, LED lighting fixtures will really make your Corvette stand out with a present day and complex 1992 corvette remover tail lights for led load resistor attraction.

5. Faster Response Time

LED lighting fixtures have the gain of lights up instantly when activated. This brief reaction time can be especially beneficial for brake lighting fixtures and turn signals, offering faster notification to different drivers. In situations wherein every 2d counts, this rapid illumination could make a noticeable distinction in protection, as it reduces reaction time for cars behind you.

Challenges and the Need for Load Resistors

While the benefits of LED tail lights are clean, the upgrade procedure isn’t usually as simple as replacing the bulbs. Due to the decrease electricity intake of LED lighting, your 1992 Corvette’s electric machine can also interpret this as a malfunction, frequently ensuing in rapid blinking or hyperflashing of the tail lighting fixtures. To solve this problem and make sure your new LEDs feature well, you could want to put in a load resistor.

A load resistor allows balance the electric modern-day 1992 corvette remover tail lights for led load resistor to simulate the power draw of conventional incandescent bulbs, removing the hyperflashing problem and restoring everyday functionality. This small however vital aspect ensures that your LED lighting paintings seamlessly together with your vehicle’s device.

How to Install Load Resistors for LED Tail Lights in Your 1992 Corvette

Upgrading to LED tail lighting to your 1992 Corvette can notably enhance the aesthetics and ordinary overall performance of your vehicle. However, to make certain the right functioning of your new LED lighting, you could need to install load resistors.These components assist solve problems like hyperflashing, that could occur when the LED lighting fixtures draw much less power than the same old incandescent bulbs. Here’s a clean and clean-to-comply with guide that will help you installation load resistors for LED 1992 corvette remover tail lights for led load resistor tail lighting fixtures on your Corvette.

1. Select the Appropriate Load Resistor

Before you begin, it’s vital to pick out the proper load resistors which might be well suited together with your LED tail lights. Look for resistors that healthy the power necessities of your unique LED lighting. This will make sure that the resistor features efficiently and forestalls problems with your vehicle’s electric gadget. Check 1992 corvette remover tail lights for led load resistor the product details or consult the manufacturer for an appropriate specs.

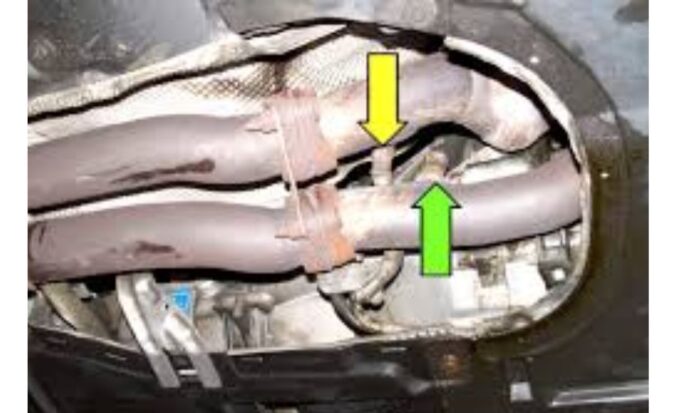

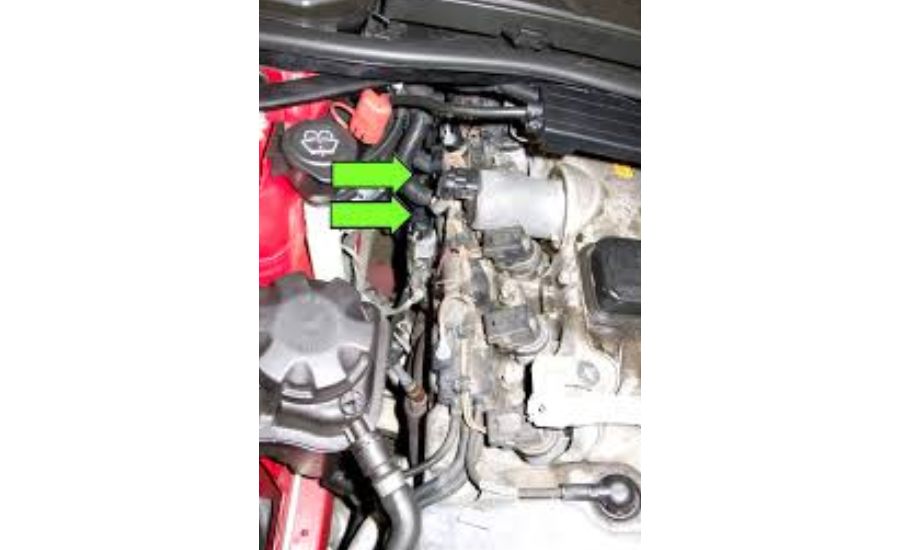

2. Identify the Wiring Harness

The subsequent step is to locate the tail moderate wiring harness in your Corvette. The harness is normally positioned within the trunk or inside the returned of the rear bumper. If you are uncertain approximately its real area, discuss with your car’s guide or search for on line guides tailor-made to the 1992 Corvette version. The wiring harness is wherein you’ll be making the connections for the burden resistor.

3. Connect the Load Resistor

Once you’ve placed the wiring harness, you’ll want to connect the load resistor in parallel with the LED tail light circuit. This normally involves splicing 1992 corvette remover tail lights for led load resistor into the cord that powers the tail mild. It’s vital to observe the wiring commands supplied with the resistor to make certain right connection. Be certain to apply first rate connectors or electric tape to steady the connections and avoid any free wiring that could purpose malfunction.

4. Mount the Load Resistor

Load resistors generate heat for the duration of operation, so it’s crucial to mount them in a area that lets in for adequate air flow. One of the excellent practices is to attach the resistor to a metallic floor, such as the body of the automobile. This enables deplete heat efficiently and prevents overheating. Ensure that the resistor is mounted securely and far from any components that could be damaged through the heat.

5. Test the Tail Lights

After completing the installation, it’s time to test the lighting fixtures. Turn for your automobile and take a look at the tail lighting fixtures to make certain that the rapid flashing or hyperflashing has been resolved. If the lights are functioning well, the blinking charge have to go back to everyday. If the problem persists, double-test your wiring and connections to make sure the whole lot is installation successfully.

Common Questions About Load Resistors

When upgrading to LED tail lighting fixtures for your 1992 Corvette, you would possibly have a few commonplace questions about load resistors and their role. Let’s deal with those often requested questions to offer clarity and ensure 1992 corvette remover tail lights for led load resistor you’re well-informed approximately the technique.

1. Do I Need Load Resistors for All LED Lights?

Not every LED mild calls for a load resistor. Typically, load resistors are vital for flip sign and tail light enhancements, as those circuits are more sensitive to the lower electricity draw of LED lights as compared to traditional incandescent bulbs. In assessment, other LED lighting fixtures, which include brake lighting fixtures, won’t usually want resistors, relying on how the car’s electrical device is designed. It’s constantly recommended to confirm whether your particular car desires resistors on your LED lighting fixtures.

2. Are Load Resistors Safe to Use?

When mounted effectively, load resistors are absolutely secure and play a important position in making sure your LED lighting gadget operates as supposed. They work by simulating the electricity draw of traditional incandescent bulbs, stopping electric problems like hyperflashing. Proper installation is critical for protection, because 1992 corvette remover tail lights for led load resistor it ensures that the resistors don’t overheat or purpose any damage to the electric components of your automobile.

3. Can I Use an Alternative Method to Prevent Hyperflashing?

Yes, there is an opportunity approach to using load resistors. Some automobiles provide the choice to replace the usual flasher relay with a virtual flasher relay, which also can help remove hyperflashing. This approach is effective and removes the need for load resistors. However, for most Corvette proprietors, load resistors remain the maximum on hand, truthful, and cost-powerful method for fixing hyperflashing issues when upgrading to LED tail lighting fixtures.

What is an LED Load Resistor?

An LED load resistor is a crucial thing designed to imitate the resistance that conventional incandescent bulbs produce. LEDs, being more electricity-efficient, draw a lot much less power than incandescent bulbs. This low electricity draw can purpose compatibility problems with a vehicle’s electrical machine, leading to malfunctions like rapid blinking of turn signals or failure of tail lighting to perform efficaciously.

In older motors, which include the 1992 Corvette, the wiring and electric systems have been engineered to work with incandescent bulbs. When LEDs are delivered, the device may interpret the reduced power intake as a bulb failure,1992 corvette remover tail lights for led load resistor triggering faster blinking or no lighting in any respect. The load resistor resolves this by means of introducing additional resistance into the circuit, allowing the automobile’s electric gadget to properly understand and feature with the brand new LED lights, ensuring they perform as supposed.

By including a load resistor, you assist make certain 1992 corvette remover tail lights for led load resistor the automobile’s turn signals and tail lights perform at their best, offering dependable capability and stopping issues associated with energy draw and sign velocity.

Why is a Load Resistor Crucial for Upgrading to LED Tail Lights in Your 1992 Corvette?

When upgrading to LED tail lighting on your 1992 Corvette, putting in a load resistor is fundamental to making sure proper capability along with your vehicle’s electric system. While LED lighting fixtures are desired for his or her energy performance, sturdiness, and smooth look, they draw considerably much less strength than traditional incandescent bulbs. This difference can purpose compatibility issues, that may effect your vehicle’s lighting device.

Here’s a breakdown of the principle troubles which could get up without a load resistor:

- Hyperflashing: One of the most not unusual 1992 corvette remover tail lights for led load resistor issues whilst putting in LEDs is hyperflashing. This occurs while the turn sign blinks at an abnormally rapid fee. The Corvette’s electrical device expects a higher strength draw from the bulbs, and the decreased load from the LEDs triggers the machine to interpret this as a malfunction, leading to the speedy blinking of the flip signal.

- Non-Functioning Tail Lights: In a few instances, the electric machine might also fail to recognize the new LED lights completely. As a end result, the lights gained’t switch on due to the fact the device isn’t detecting the precise resistance.

- Error Messages or Warning Lights: Your 1992 corvette remover tail lights for led load resistor dashboard may show an blunders message, including a “bulb-out” warning, even though the LEDs are functioning. This takes place due to the fact the low power intake of the LEDs is misinterpret by means of the machine as a fault inside the bulb.

By installing a load resistor, you offer the essential resistance to balance the strength consumption, permitting the electric system to understand the brand new LED lighting fixtures as absolutely purposeful. This guarantees that your 1992 corvette remover tail lights for led load resistor Corvette’s tail lighting paintings easily, providing steady overall performance with out errors messages or malfunctioning signals.

Advantages of Installing a Load Resistor for LED Tail Lights in Your 1992 Corvette

Upgrading to LED tail lighting fixtures on your 1992 Corvette, along side the critical installation of a load resistor, brings numerous valuable advantages, ensuring that your car’s lighting fixtures tool operates seamlessly. Here’s how the usage of a load resistor can beautify your car:

- Eliminates Electrical Malfunctions: A load resistor prevents commonplace issues like hyperflashing or non-useful LEDs with the 1992 corvette remover tail lights for led load resistor aid of ensuring the electrical device efficiently acknowledges the cutting-edge LEDs. This ensures that your lighting operate really as they ought to, with none interference from wrong resistance readings.

- Improves Safety: Properly functioning tail lighting are crucial for secure riding, particularly at night time time or in low visibility conditions. A load resistor helps ensure that your LED tail lights perform optimally 1992 corvette remover tail lights for led load resistor, allowing extraordinary drivers to be aware your flip signals or brake lights with out confusion, improving average avenue protection.

- Enhances the Aesthetic Appeal: LED tail lighting offer a swish, present day look that substantially elevates the advent of your 1992 Corvette. The crisp, shiny lighting now not nice improves visibility however additionally provides a hint of contemporary fashion in your automobile, giving it a immoderate-give up, upgraded appearance.

- Reduces Long-Term Maintenance Costs: LEDs are recognised for his or her durability and longer lifespan in contrast to standard 1992 corvette remover tail lights for led load resistor incandescent bulbs. With a load resistor set up, you can revel in the benefits of reduced preservation charges, as LED lighting fixtures require fewer replacements, saving you money and time in the end.

By ensuring smooth electric performance and enhancing both protection and style, the installation of a load resistor for.

Facts:

- LED Tail Lights for 1992 Corvette: Upgrading to LED tail lights offers improved visibility, a modern aesthetic, longer lifespan 1992 corvette remover tail lights for led load resistor, energy efficiency, and faster response times for your 1992 Corvette.

- Benefits of LED Upgrade: LED lights are brighter, more energy-efficient, and last longer compared to traditional incandescent bulbs. They also provide a sleeker, more contemporary look to your vehicle.

- Common Issue – Hyperflashing: When upgrading to LEDs, your Corvette’s electrical system might interpret the reduced power 1992 corvette remover tail lights for led load resistor draw of LEDs as a malfunction, leading to issues like hyperflashing or non-functioning tail lights.

- Role of Load Resistor: A load resistor simulates the power draw of an incandescent bulb, fixing issues like hyperflashing and ensuring your LEDs work properly with the car’s electrical system.

- Installation: Installing a load resistor involves selecting the correct resistor, identifying the wiring harness, connecting the resistor in parallel, mounting it in a well-ventilated location, and testing the tail lights to ensure proper functioning.

Summary:

Upgrading to LED tail lights on your 1992 Corvette provides enhanced visibility, energy efficiency, and a sleek, modern look. However, to 1992 corvette remover tail lights for led load resistor ensure these benefits, it’s essential to install a load resistor. The resistor prevents electrical issues such as hyperflashing, non-functioning tail lights, and error messages by balancing the power draw between the LED lights and the car’s electrical system. Installation involves choosing the appropriate resistor, connecting it properly, and ensuring adequate ventilation to prevent overheating. With proper 1992 corvette remover tail lights for led load resistor installation, your new LED lights will function seamlessly, offering improved safety and a stylish appearance, while also reducing long-term maintenance costs.

FAQs:

- Why do I need a load resistor for LED tail lights?

A load resistor simulates the power draw of traditional incandescent bulbs, preventing issues like hyperflashing or non-functioning tail lights when upgrading to LEDs.

- Can I install LED tail lights without a load resistor?

While technically possible, installing LED 1992 corvette remover tail lights for led load resistor tail lights without a load resistor may result in issues like hyperflashing or error messages on your dashboard.

- How do I install a load resistor for LED tail lights?

Select the correct load resistor, locate the wiring harness, connect the resistor in parallel with the LED circuit, mount it securely, and test the tail lights.

- Are load resistors safe to use?

Yes, when installed correctly, load resistors are safe and help ensure proper functionality of your LED tail lights without causing electrical malfunctions.

- How long do LED tail lights last compared to incandescent bulbs?

LED tail lights typically last much longer than incandescent bulbs, reducing the need for frequent replacements and saving you on 1992 corvette remover tail lights for led load resistor maintenance costs.

- Can I avoid using a load resistor with a digital flasher relay?

Yes, some vehicles offer a digital flasher relay that can also resolve hyperflashing without the need for load resistors. However, for most Corvette owners, load resistors are a more accessible and cost-effective solution.

- Will upgrading to LED tail lights save on energy?

Yes, LEDs consume significantly less power than incandescent bulbs, which can help preserve your car’s battery life and reduce 1992 corvette remover tail lights for led load resistor stress on the electrical system.

Read more about Auto at Visit SearchKnowledge